Marketing a new pharmaceutical drug is more than just designing an eye-catching package that will attract customers. As pharmaceutical medicine can help the human body, misinformation or lack thereof can cause detrimental effects to consumers who buy the drug, whether over the counter or as a prescription.

Both the design of the package and the information that is printed need to ensure that there is minimal risk to consumers and that the packaging won’t break easily. In addition, clinical research consultancy services provided by qualified regulatory consultants can be critical to the successful completion of a clinical study, visit https://www.rondaxe.com/what-exactly-are-clinical-research-consultants/ to know more.

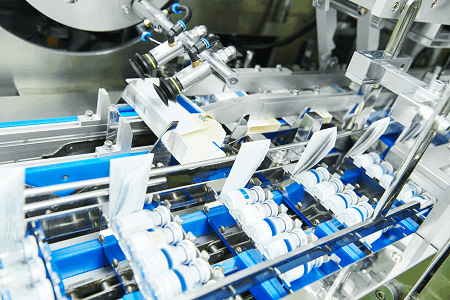

Here are 5 ways that designing and manufacturing pharmaceutical packaging can be done efficiently.

Hermetic Sealing

This packaging refers to any substance that will make a package airtight. Some manufacturers use glue or lubricant that is heated through induction heating to close the seal. Hermetic sealing requires at least 200 degrees Fahrenheit to properly seal any container.

This tip is ideal for packaging that contains products that can’t be exposed to sunlight, oxygen, or any outside moisture. Sealing a package this way ensures that no bacteria can get in and infect the product. It is important to hire pharmaceutical courier service when transporting pharmaceutical products because they know the right way of handling these products.

Specialized Printer Solutions

An incorrectly printed instruction that shows 10mg should be taken instead of 1.0mg is a major issue. If the medication has been prescribed, chances are it will be potent, and a difference of 9mg could mean serious health implications. Diagraph specializes in manufacturing printing technology for labels, products, and nutritional information, which can help mitigate issues.

You can also use Dymo compatible labels if you have Dymo thermal direct printers.

There is a medical solution available that already has FDA compliance checks and precautionary software in place that manage specific drug types and different interactions.

High-Quality Material

Some types of medication can’t be stored with others due to cross-contamination, which can affect the strength of the drug. For pharmaceutical packaging, manufacturers often use cyclic olefin polymers as an option for transparent and shatterproof bottles.

Cyclic olefin polymer can be stored at very low temperatures and is quite safe to transport. Although the initial investment is more than another plastic-based packaging, this polymer decreases the chances of product recall and packaging fails.

Manufacturing Partnerships

When it comes to medicine and pharmaceutical drugs that are used to treat illness, the Food and Drug Administration (FDA) has strict compliance rules in place that stipulate how manufacturers need to package and transport their products. As the process can be quite daunting and the compliance checks are very involved, it would be wise to hire FDA regulatory consulting services and employ a manufacturing partner who is specialized in packaging pharmaceuticals.

Pharmaceutical packaging partnerships are beneficial for all involved, as specific sterilization processes are taken care of that ensure the packaging is safe. These types of companies are also FDA-approved, and experts in safely packaging various medicines.

Human error is common and will always happen. For pharmaceutical products, errors in printing can cause major issues, especially in legal ways. If there is a typo on the packaging, no matter how small, it can change the meaning of the instructions entirely. To avoid overdoses, unsafe packaging, and negative interactions with other drugs, it is critical that pharmaceutical packing is designed and manufactured in a safe and regulated manner. In addition, the use of Pharmaceutical Systems Solutions can improve your processes through reliable data collection and monitoring. With the help of our pharma systems solutions, you can easily identify areas of inefficiency in the system and quickly correct them.